Modular Design Of Prefabricated Buildings In The Context Of BIM

The construction industry is currently facing a sharp problem of low production efficiency, as urbanization continues to accelerate nationwide. Luckily, the rapid development of BIM technology is providing the much-needed impetus. According to a 2004 investigation from Stanford University, over a 40-year period, the productivity of the US construction industry decreased by 20% compared to non-agricultural production. A more serious issue is the information isolation and expression errors between various specialties during the design process, leading to frequent transmission errors and omissions. However, the use of BIM can completely change this situation and greatly improve construction efficiency.

The demand for information has increased due to the widespread use of computers and communication devices. BIM technology emerged as a digital model system that integrates all stages of building construction. BIM can be Building Information Model or Building Information Modeling, originating from Charles Eastman and Autodesk. BIM enables visualization, quantification analysis, digital collaboration, and information exchange, contributing to improving efficiency and quality in building design, construction, and operation management.

The Synergy of BIM Technology and Modular Thinking in Building Design

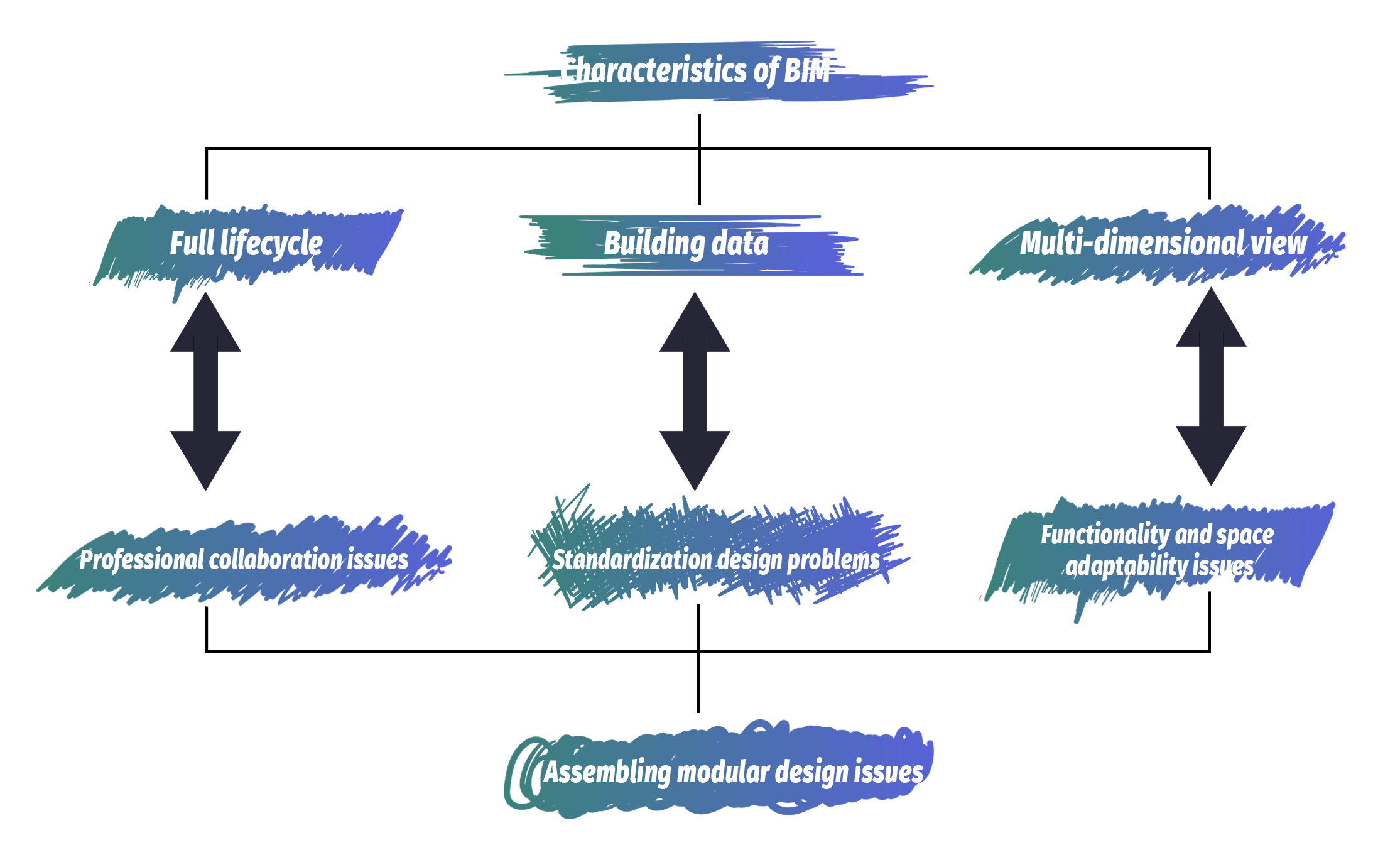

① BIM is a new technology for building structure and construction, including Building Information Modeling and Building Information Management. It’s like CAD, improving design and seen as a 3D tool using components. BIM provides more detail than past tools and improves design accuracy. With industrial development, BIM is now necessary for projects. More prefabricated buildings use BIM for better design and project accuracy. The greatest advantage of BIM is analyzing products during selection, placing space based on component size, and imagining the final effect of space.

When using BIM for design, designers must consider how to create it, graphic quality, and model updates. Actual materials and building information must be added to the model to assist the design process. BIM changed the work of architects, engineers, and contractors, promoting team collaboration and adding more information before development. Traditional design separates documents and design, with no direct relationship between elements. However, BIM regards design as a whole, with direct connections between each component. Design no longer consists of simple line relationships; each building component can have specific properties added.

② BIM technology revolutionized building design and construction, outperforming traditional 2D or 3D computer-aided technologies. Initially, CAD drew simple lines faster than manual sketching, with the addition of layer and line features further advancing it. As the industry moved toward 3D modeling, BIM emerged and allowed the addition of attributes to each building component. BIM information is crucial for accuracy, analyzing, and decision-making in design, such as thermal analysis to distinguish different walls. A “digital prototype” can be made to assess design components’ value and issues. BIM is gaining popularity in prefabricated building design and contributing to improved accuracy and precision in construction projects.

③ The integration of BIM technology and modular thinking originated from the design concept of lathes in the manufacturing industry. To enhance automation and reduce specialized equipment requirements, lathes designers utilized modular thinking by creating different structure modules with various functions and purposes. These modules could be combined to form a product with numerous functions. The manufacturing industry often decomposes complex production processes into different hierarchical modules, with each module independently completing different tasks to increase efficiency and production quality. Therefore, combining BIM tech and modular thinking can improve building design, enhance construction efficiency and quality, and allow for more digital innovation possibilities.

BIM is a concept proposed for construction projects, which effectively controls actual engineering projects through models containing a large amount of data. BIM theory stems from the need to enhance work efficiency in the industry. It can significantly improve the level of information in construction projects, and reduce potential construction risks. In modern society, various obstacles exist in information transmission between specialties. The emergence of BIM information technology effectively connects the upstream and downstream of the industry through information integration, making good collaboration possible. BIM integrates a plethora of functions and information in a single module, which coincides with the concept of high integration and modularization.

==============================================================================================================================================

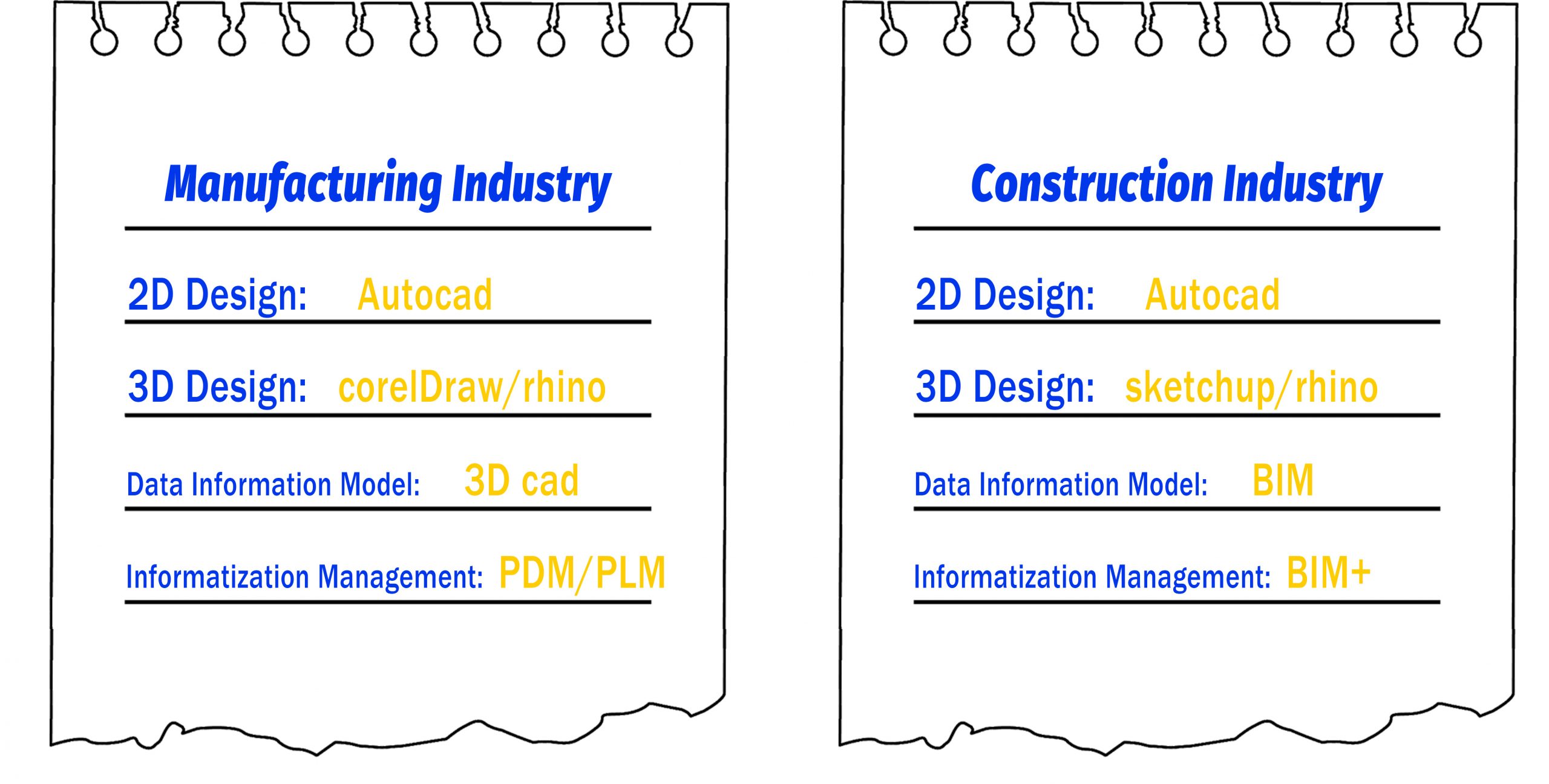

The development of prefabricated buildings is closely related to the manufacturing industry. Modular thinking was first practiced in manufacturing before being extended to the construction industry. Building efficiency still lags behind manufacturing. The emergence of BIM technology aims to improve the information level and construction efficiency of the construction industry.

With the demand for industrial production, the informationization development of the manufacturing industry has matured and can be divided into three levels. The first level involves the innovation of image design methods, including the handling of 2D and 3D images. Professional software like AUTOCAD, Alias, and Rhino provide excellent platforms for this. The second level is 3DCAD, in which the three-dimensional model is introduced into the manufacturing industry as an important component to achieve higher informationization standards. The final level involves product information management, including the application of PLM and PDM, which can manage and communicate lifecycle-related information and improve production efficiency and product quality. These technologies in the three-level system have successfully enhanced the manufacturing industry, particularly in sectors like automobiles, electronics, and aerospace by promoting rapid development and optimization of the overall workflow.

Therefore, the application of BIM technology in the construction industry is a necessary step towards informationalization. With the continuous research of BIM (Building Information Modeling) in the construction industry both domestically and abroad, the technology has not only promoted the development of the industry but also brought new concepts. From 2002 to 2009, BIM technology was introduced in the industrial sector, and the United States has remained a leader in this field, representing the global development of BIM technology. Currently, BIM is increasingly valued in the industry, and its value continues to grow in practical applications.

==============================================================================================================================================

Revolutionizing Prefabricated Building Design with BIM Technology

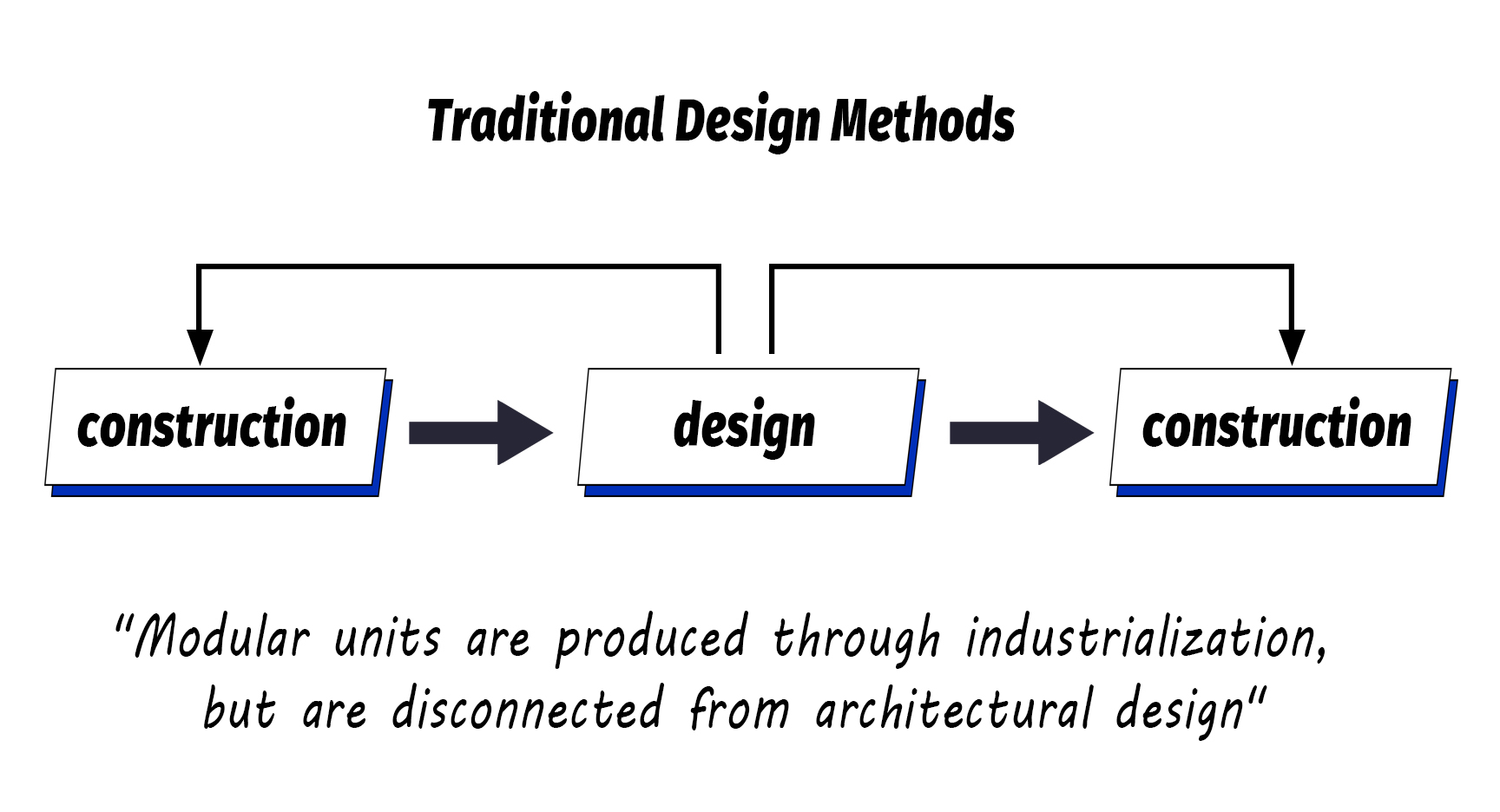

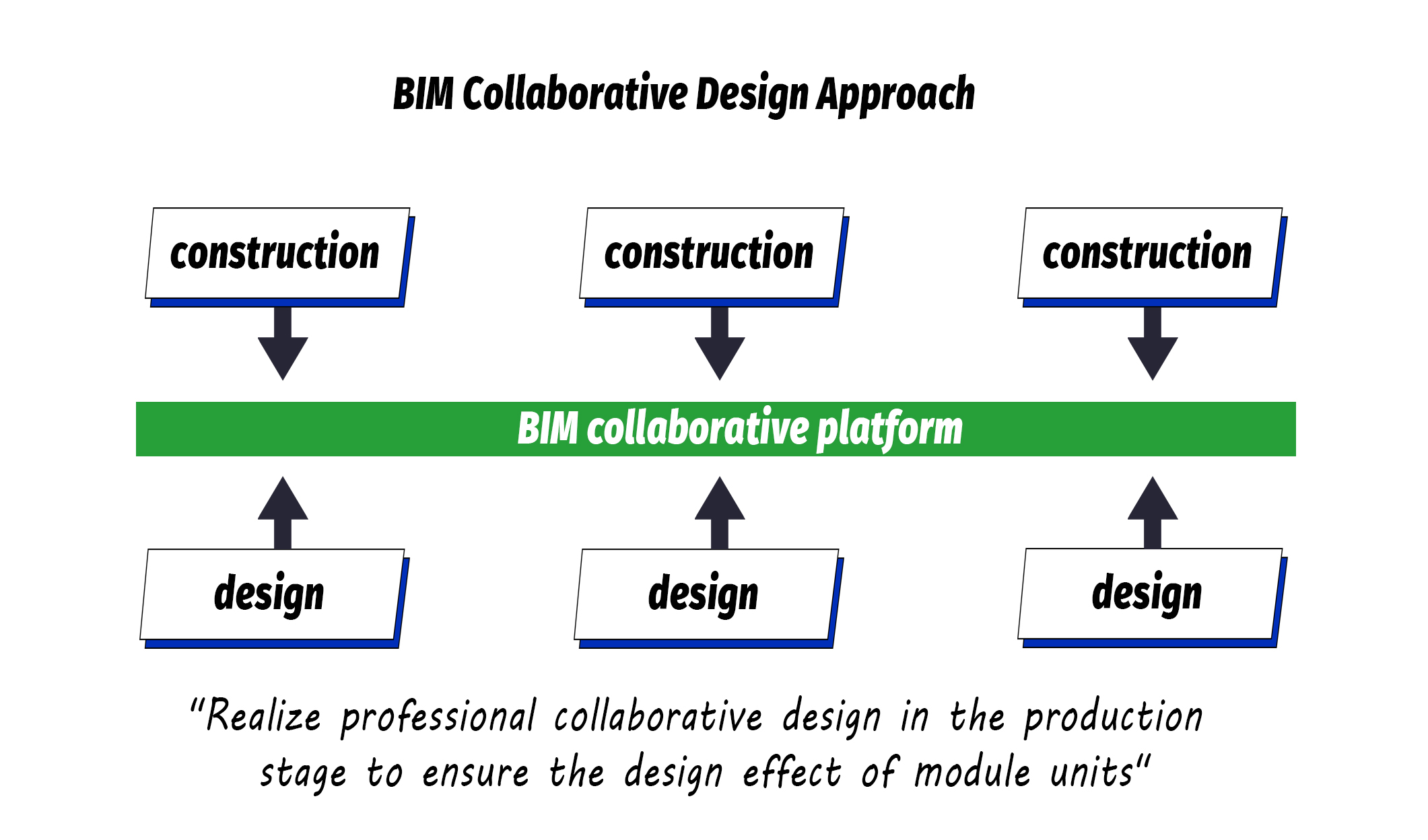

(1)Collaboration between design and construction requirements

BIM’s introduction has led to dramatic changes in the original building design process. One major change is the popularity of the concept of “Master Model”. It expands architects’ control range from design stage to full cycle, allowing for more comprehensive consideration of the entire building’s situation, improving the connection between design and construction and mitigating the separation between construction and design. In modular prefabricated building design, pre-fabricated modular units play a major role. Therefore, module unit quality and design/construction quality are closely related and directly determine the effectiveness of the building’s later stages.

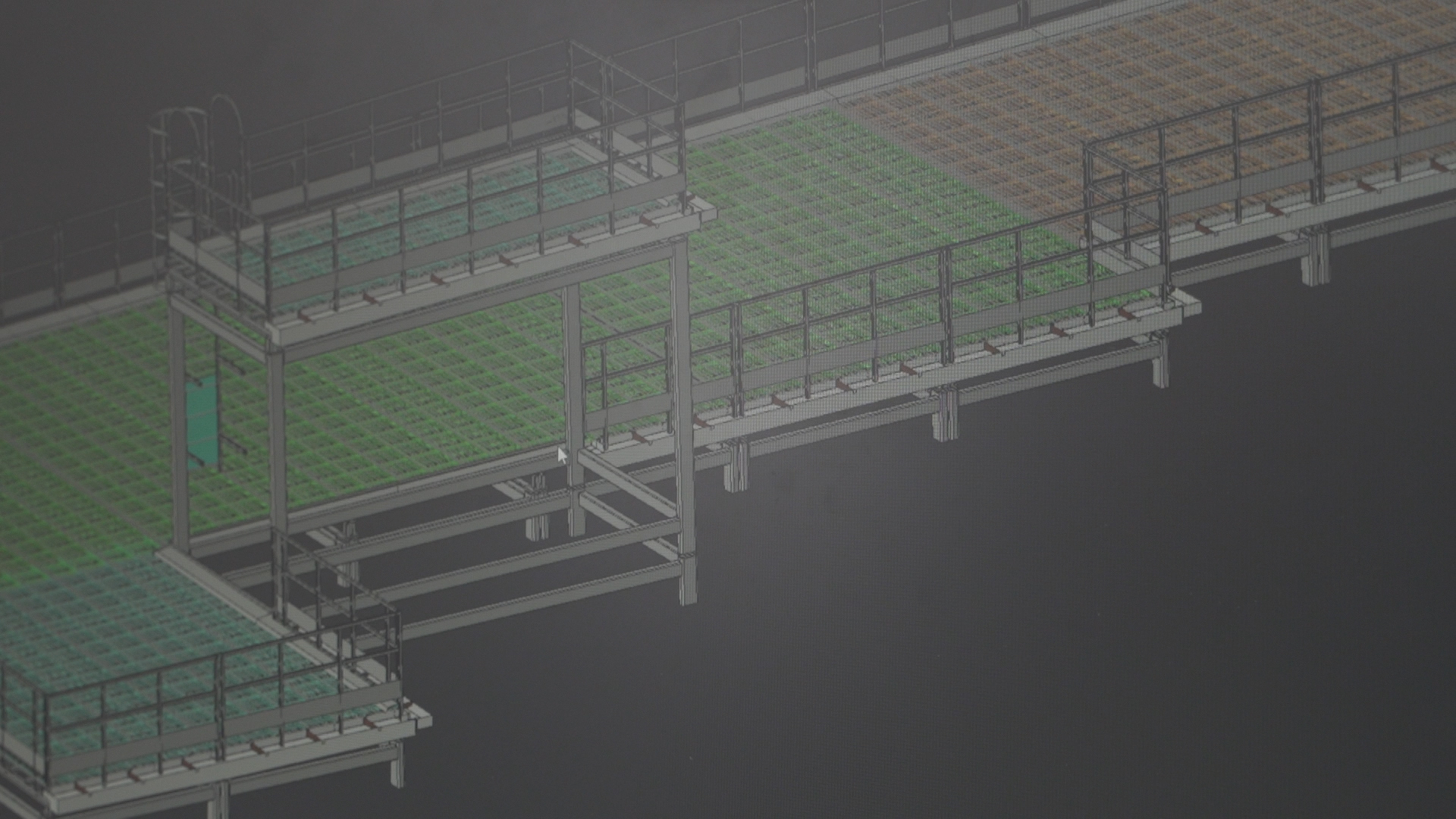

The common design pattern for module unit is that factories manufacture them first and then architects get involved and perform in-depth design. This pattern is then used in prefabricated building design.Using BIM technology, cross-disciplinary coordination can be achieved from the beginning, ensuring that the module units consider a series of design issues during prefabrication production.

(2)Emphasis on module unit design

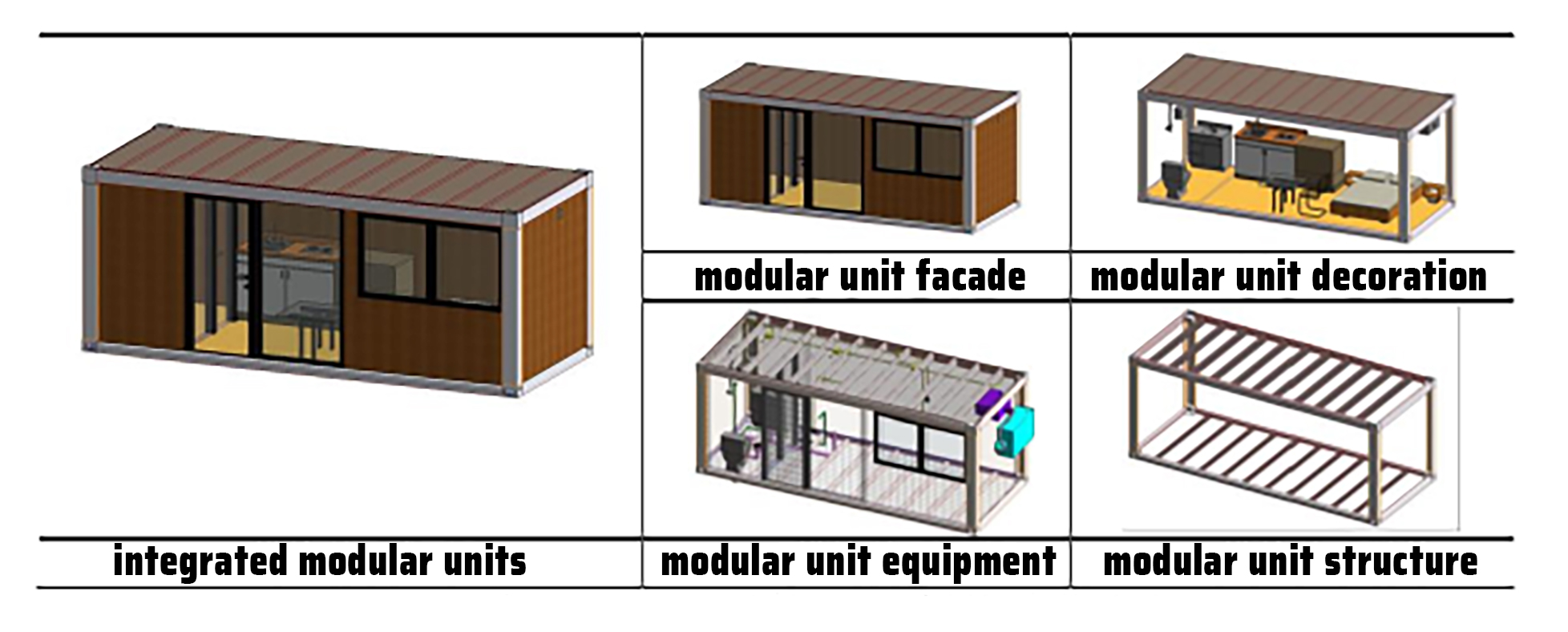

Modular design is crucial in prefabricated construction. It focuses on the design of module units and their adaptability. Unlike traditional design methods, which consider site conditions before designing the building, modular design emphasizes designing module units first and then assembling them to form the entire building. Therefore, module units require high environmental adaptability to meet the application needs in different environments.

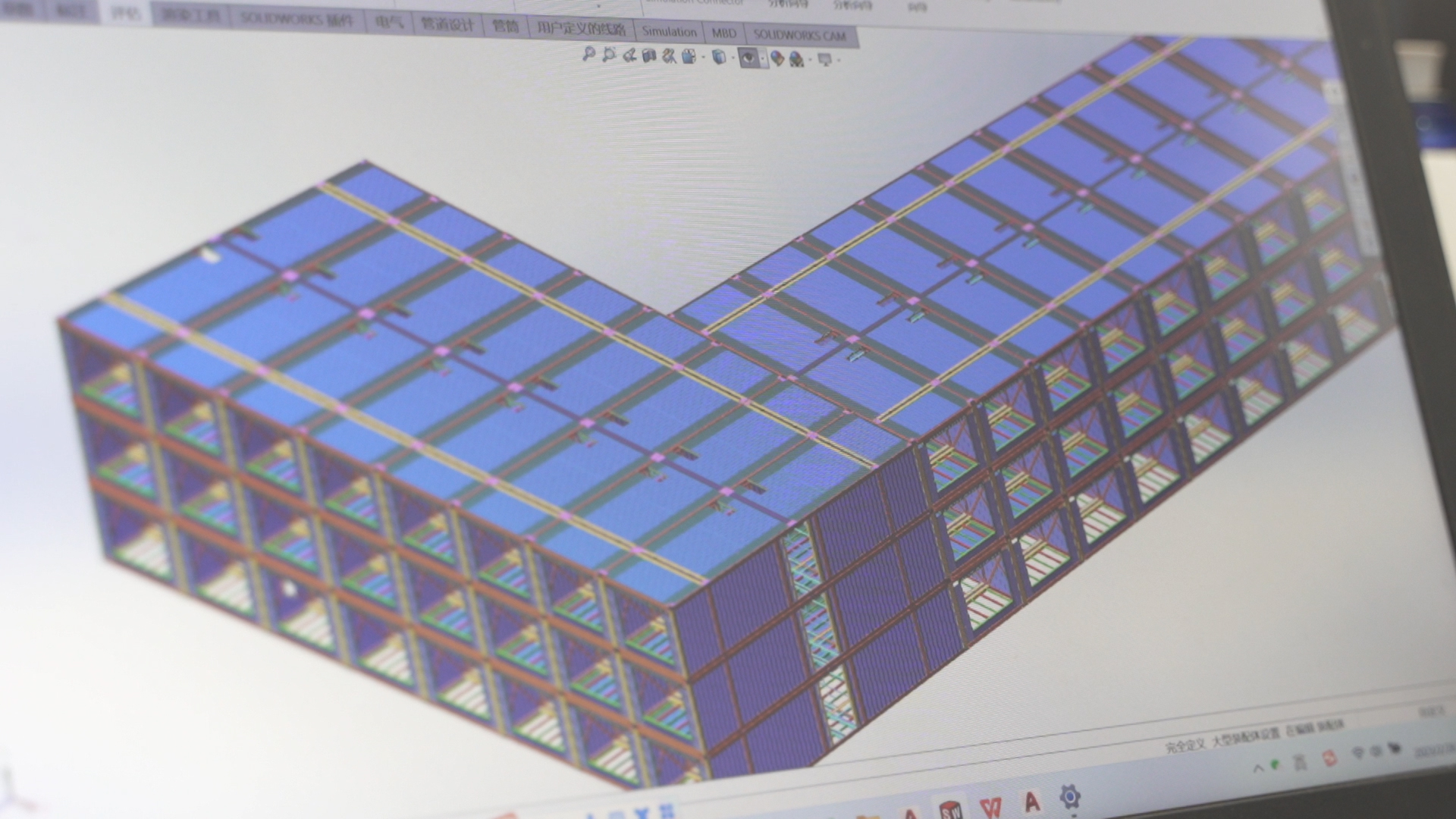

In the process of module unit design, it is important to consider the composition and design of its main components, combining with industrial manufacturing conditions to design module units that meet production requirements. BIM’s full life cycle application allows designers to extend the design process to the construction and operational stages, taking a more comprehensive perspective on design issues. For example, BIM virtual construction technology can accurately reflect the construction process of module units, detect problems with component connections early, and adjust design plans in advance.

The Advantages and Applications of BIM Technology in Building Design and Production

(1)BIM technology is a great tool for architects to design buildings. In the past, architects only drew 2D pictures of buildings, which only showed where things should be placed. But with BIM, architects can include more information about the building, like what materials it’s made of, how it’s structured, and how it performs in different temperatures. This information is stored in a database, and it’s used to create a 3D model of the building that’s much more detailed than a regular drawing. BIM also helps architects make sure that all the different parts of the building fit together correctly. For example, if you change one part of the building, like the size of a room, BIM will automatically adjust all the other parts of the building that are affected by that change. Finally, it’s important to follow the rules when designing with BIM. There are certain requirements that must be met, like how thick walls need to be, and BIM will make sure you don’t break those rules.

However, in traditional design, designers need to manually set conditions. Although complex spatial relationships can be drawn, the model only reflects the logical relationships between forms, and does not contain real construction information and data. In contrast, BIM’s model components are all in a mutually linked database, and each component can appear in different views and can be updated and modified in real-time. An ideal BIM information model should include the following six parts:

Planning information, which can be obtained directly from the planning department.

Geographic environmental information, which can be established based on information provided by municipal and survey departments.

Geometric information, which is created by architects through design concepts and conditions.

Structural information such as structural dimensions, which are calculated and created by structural designers in corresponding structural models.

Electrical and HVAC information, which is designed and added to the information model by relevant equipment designers.

Building material and construction information, which is added to the information model by designers based on information provided by manufacturers.

(2)By using a BIM database, architects can combine building information in real-time during the design process. When designing modular units, it’s important to combine building equipment, furniture, and decoration as needed to make the unit more independent, like a small building. The BIM database makes it easy to see this building information in the model. For instance, a specific model with building information can be used to design the lighting, HVAC, and electrical systems within the modular unit. The BIM database is essential for achieving an integrated design of modular units.

- Prospects

In today’s global society, modular design has become a worldwide trend, gradually influencing various fields. From small household items to large-scale construction projects, modular design thinking is being adopted to improve efficiency and reduce waste. With the advancement of the Fourth Industrial Revolution, all industries will need more intelligent and integrated innovative solutions, and modular design in prefabricated construction precisely meets this demand.

Simultaneously, with the continuous development and application of building technologies such as BIM+, the deep integration of prefabricated construction and information modeling will also become possible. This integrated and collaborative approach will not only change the traditional boundaries between building industry professionals but also improve the efficiency and quality of construction projects, achieving sustainable development worldwide. In this era of globalization, informatization, and intelligence, modular design in prefabricated construction has become an important trend for the building industry to move towards a more scientific, sustainable, and innovative direction.

Matrx use BIM technology to design and produce modular buildings, which enables us to build more scientifically. If you are interested in working with us, please contact us at the following address: info@matrixliving.com.

Leave A Comment